Joby Aviation

Since leaving Skydio, I’ve been a Manufacturing Engineering Lead at Joby Aviation, where I’ve led the EPU Inverter Manufacturing Engineering Team. Since joining, my team and I have:

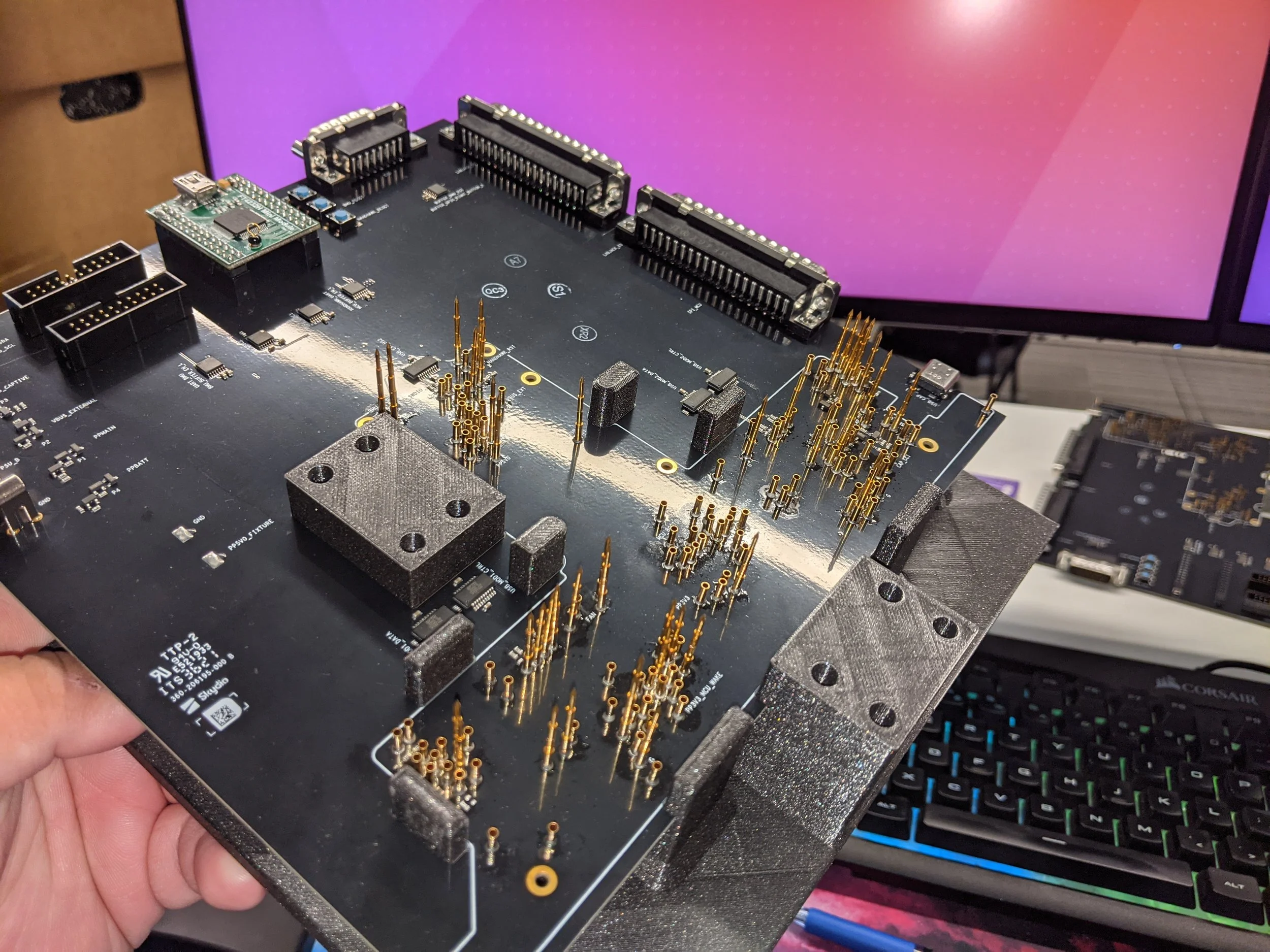

Worked closely with the design team to solve some fundamental issues between parts quality, design, and manufacturing process.

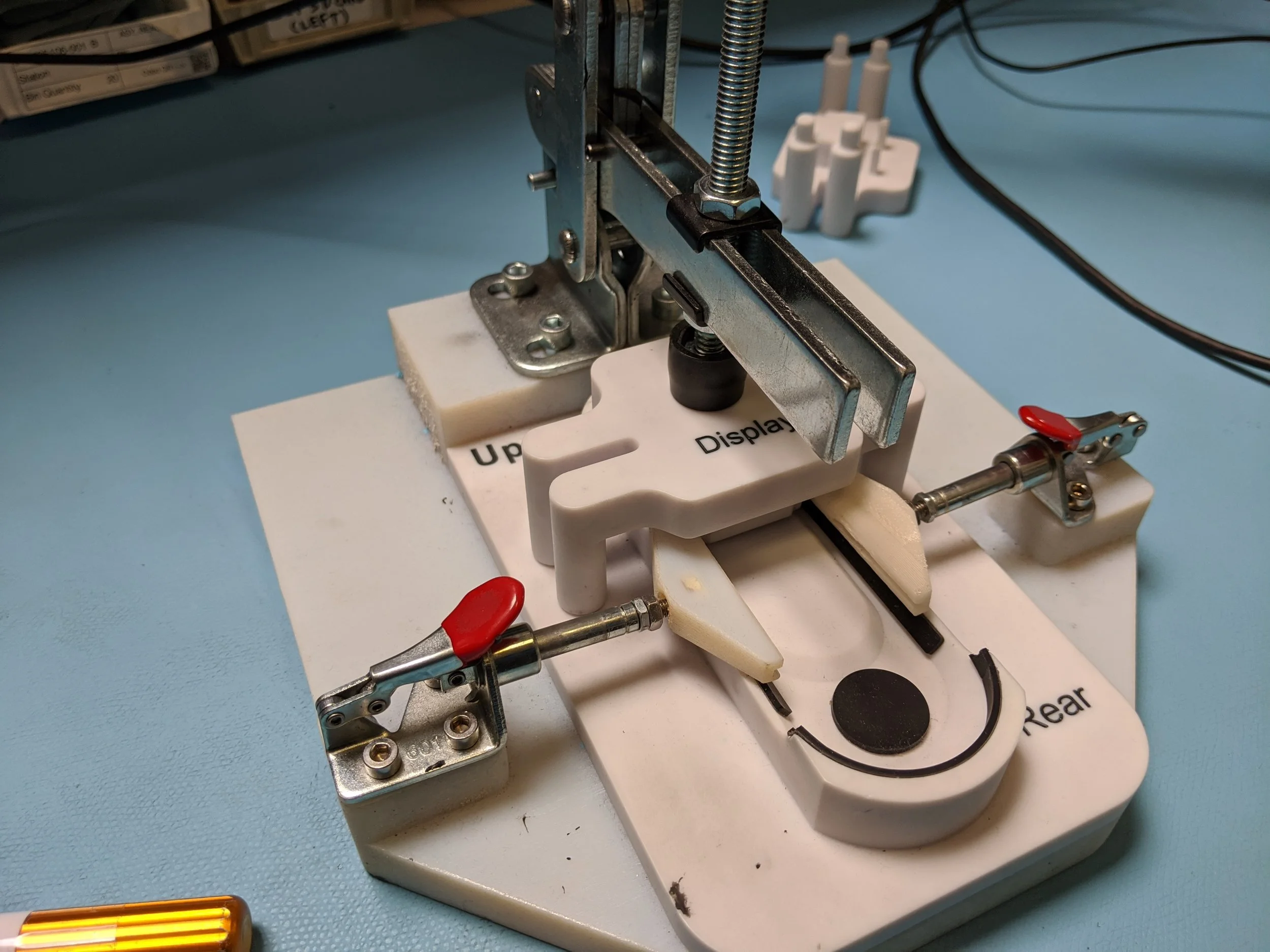

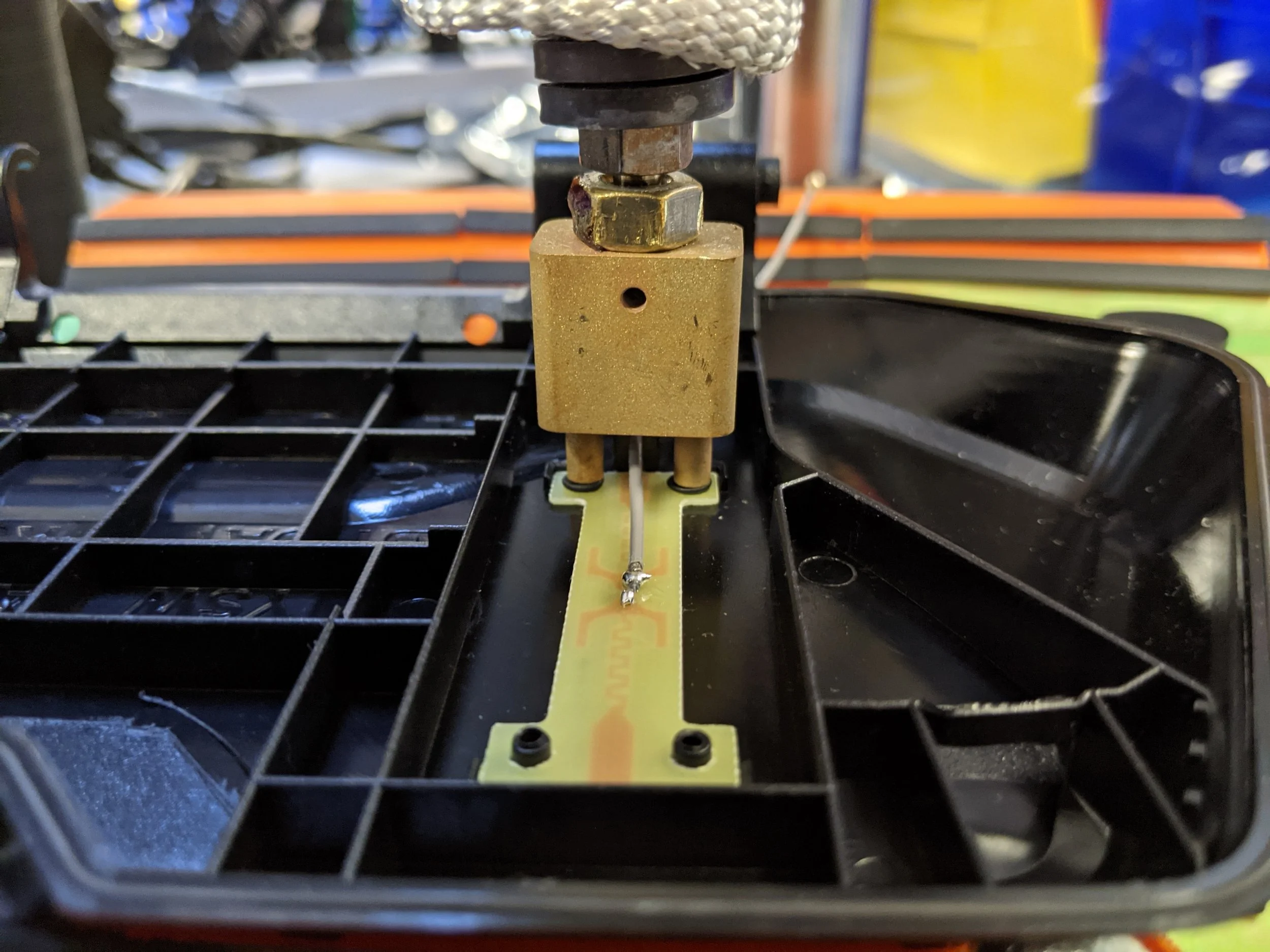

Introduced completely new processes, like full-assembly Selective Soldering and Immersion Cleaning to help solve some of those prior mentioned issues and improve process flow.

Worked to ensure production capacity will keep up with our expanding production needs, scaling from 12 airplanes a year worth of Inverters, to 48 by the end of 2026.

Performed all of the line balancing and resourcing analyses, cycle time studies, OEE calculations, and test plan development and execution to make sure we’re meeting our output goals, while also ensuring quality and functionality.

Worked cross functionally to ensure type-certifiability of the EPU Inverter and its production process, by moving through the TC Checklist, TC Audit, and TC process for the EPU Inverter.